Do you want to remodel your current house or construct a new one? Plastering material is a frequently debated yet essential building component. It's a common question: between cement plaster and gypsum plaster, which one is preferable? This article will compare and contrast the features, benefits, and applications of the two choices to help you make an educated decision.

Plaster made from sand, cement, and water is strong and long-lasting, making it ideal for wall use. Gypsum plaster, on the other hand, is created from gypsum powder, water, and additives, and it has a smooth finish and is very easy to work with. Each style has advantages and disadvantages, so picking one depends on your needs and goals.

These two choices, however, are just some of your ones when it comes to plastering. To know more about this and get the perspective of professionals in the field, we'll compare cement plaster to gypsum plaster and discuss the benefits and drawbacks of each.

With the knowledge you get from this blog, you can choose the ideal plastering material for your job, ensuring that your finished product is aesthetically pleasing and durable. Let's investigate the relative merits of cement plaster and gypsum plaster as building materials and declare a victor.

What Is Cement Plaster?

Plaster made from cement, sometimes called cement mortar plaster or just plaster, is used to coat and preserve walls and ceilings inside and out. Cement, sand, and water are combined to create this material, which is applied in a plastic or semi-liquid state and then solidifies over time to form a smooth, durable surface.

Cement plaster is applied to walls for the dual purpose of protecting and beautifying them. It protects the building from moisture, makes it more fireproof, and makes it seem better. Brick, concrete, stone, and even metal are all suitable surfaces for applying cement plaster.

Cement plaster is made by combining cement and sand in a certain ratio (usually between 1:3 and 1:6). The consistency of the mixture is adjusted by adding water very slowly. Use a trowel or spray equipment to apply the plaster to the cleaned surface.

After being applied, the cement plaster must cure to harden and strengthen. Plaster surfaces are usually kept moist with water or a curing solution while they cure. This ensures strong adhesion to the substrate and helps avoid cracking.

Cement plaster can take on various textures and finishes depending on the technique used. Textured finish, smooth troweling, sponge finish, and creating decorative patterns are all common finishing techniques. After the plaster has dried and set, it can be painted or decorated to suit personal tastes.

While cement plaster is effective for pest control, gypsum plaster, also known as plaster of Paris, has its own advantages in this aspect. Gypsum plaster provides a smooth and seamless finish, minimizing the presence of cracks or gaps where pests can hide or access your home.

Its excellent workability allows for meticulous application, creating a tight and impenetrable surface. Furthermore, gypsum plaster is fire-resistant, which can deter pests seeking refuge in vulnerable areas. By selecting gypsum plaster for interior applications, you enhance pest prevention measures while enjoying a visually appealing and pest-resistant living environment.

What Is Gypsum Plaster?

Plaster of Paris, manufactured from the mineral gypsum, is one variety of gypsum plaster. Used frequently in the construction of interior walls and ceilings.

The gypsum material used to make gypsum plaster is either mined from natural sources or obtained as a byproduct of several different types of industrial activity.

Crushing the mined gypsum into a fine powder and heating it to a high temperature removes most of the water, leaving behind a dry powder called "calcined gypsum."

After being calcined, gypsum is combined with water to create a paste that can be used to finish surfaces like walls and ceilings. This paste hardens rapidly because of a chemical reaction between the water and the calcined gypsum, known as "hydration." Chemically transforming back into calcium sulphate dihydrate, gypsum plaster becomes an extremely hard and long-lasting surface.

Gypsum plaster is widely used because of its many advantageous characteristics. Since gypsum is chemically inert, it provides excellent fire protection. It can also act as an effective sound barrier, limiting the amount of noise that can be heard from one room to another.

When properly applied, gypsum plaster creates a uniform, smooth surface ideal for painting or other ornamental treatments.

Because it is a mineral found in nature and can be reused, gypsum plaster is also considered eco-friendly. It can help maintain a comfortable and healthy interior climate by absorbing and releasing moisture as needed.

Difference Between Cement and Gypsum Plaster

Plastering, a venerable technique aimed at safeguarding a building's exposed surfaces from the elements and enhancing its aesthetic appeal, has evolved over time to incorporate diverse styles, technological advancements, and innovations.

Among these methods, gypsum plastering stands as a time-honoured practice, dating back to ancient times, alongside the more prevalent cement plastering. This article delves into the dissimilarities between these two plastering methods, highlighting their distinctive features.

Raw Materials

Cement plaster: Consisting of water, sand, and Portland cement, cement plaster allows for on-site mixing of sand and cement in various proportions. Both mixed and unmixed materials are available in different packaging options.

Gypsum plaster: In contrast, gypsum plaster employs gypsum powder instead of Portland cement and sand.

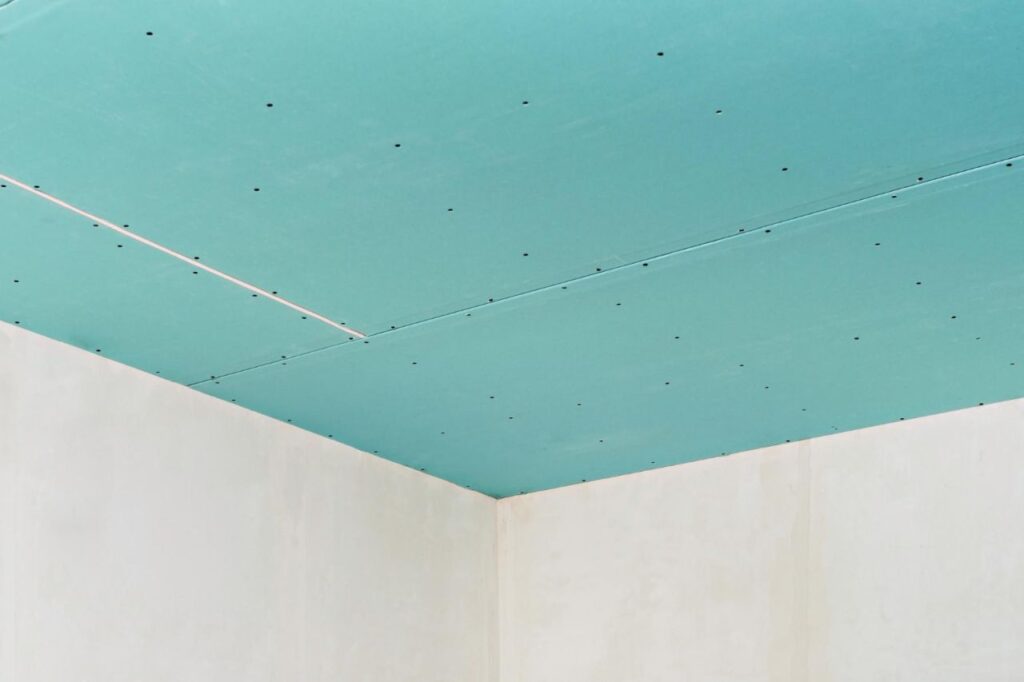

Area Recommendation

Cement plaster: Renowned for its versatility, cement plaster can be applied to both interior and exterior surfaces.

Gypsum plaster: On the other hand, gypsum plaster finds its utility limited to interior walls and ceilings. Its unsuitability in damp environments, such as bathrooms, kitchens, and laundry rooms, further reinforces this restriction.

Setting Time

Cement plaster requires a minimum drying time of one day between successive layers. After drying for 48 hours, interior cement-based coats can be added.

Gypsum plaster possesses adjustable setting times, allowing for swift application of subsequent coats with minimal waiting periods.

Thickness

Cement plaster necessitates a minimum thickness of 10 mm, although different thicknesses may be employed depending on the surfaces being coated and their alignment and texture.

For gypsum plaster, an undercoat of 11 mm thickness is recommended for walls, while ceilings require an 8 mm thick undercoat. The finishing coat should be 2 mm thick.

Non-Toxic and Anti-fungus Properties

Cement plaster exhibits limited permeability to vapor, leading to the growth of mold and mildew on bathroom or kitchen walls. The dampness can also render the floor slippery.

In contrast, gypsum plaster proves impervious to pests and discourages the formation of mold and mildew. It finds regular application in medical facilities due to its hygienic attributes.

Consumption

For cement plaster, a 40-kilogram bag is sufficient to cover approximately 16 to 18 square feet of floor space when utilizing a mortar mix with a 1:4 ratio, resulting in a 12-millimeter coat.

With gypsum plaster, a 25-kilogram bag can cover an area ranging from 18 to 21 square feet, indicating a higher proportion of gypsum plaster compared to cement plaster to achieve the same coverage.

Weight

Cement plaster possesses greater density than gypsum plaster, exerting a heavier load on the supporting structure. Additionally, it requires more water to attain equivalent strength.

Gypsum plaster, being air-based, boasts a lighter weight. Its formability further contributes to its lightweight nature.

Acoustic Properties

Both cement plaster and gypsum plaster offer comparable acoustic qualities.

Gypsum, when utilized as a binding agent in the production of acoustic tiles and plasters, aids in the attenuation of airborne noises.

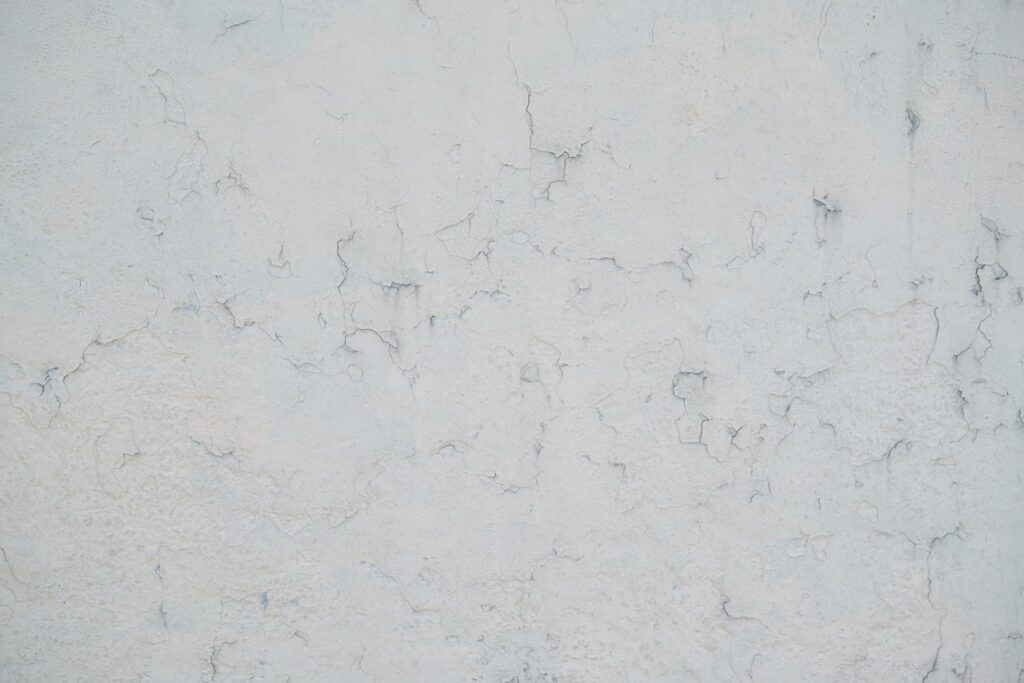

Absence of Shrinkage Cracking

Cement plaster is prone to shrinkage cracks during the drying and hardening process, a common occurrence with this material.

Conversely, gypsum plaster does not experience shrinkage during the drying process, thereby mitigating the occurrence of cracks.

Cost

The application time required for cement plaster contributes to higher overall costs. Conversely, although gypsum plaster carries a higher price per square foot, its usage can reduce labor expenses and expedite the construction process.

As a result, gypsum plaster proves costlier than cement plaster when considering the same thickness.

While both cement plaster and gypsum plaster serve distinct purposes in the realm of plastering, their disparities in terms of raw materials, application area, setting time, thickness, properties, consumption, weight, acoustic attributes, susceptibility to cracks, and cost make them suitable for different scenarios.

Understanding these differences allows professionals and homeowners to make informed decisions when selecting the most appropriate plastering method for their specific requirements.

Expert Tips For Plaster Application And Maintenance

Do you wanna know the secret to a long-lasting, perfectly smooth plaster finish? Stop right there!

Our professional guidance will help you become a better plasterer. We'll help you with every step of the plastering process, from selecting the right materials to achieving a professional finish.

Learn the techniques experts use to create beautiful, long-lasting surfaces that can be used indoors or out.

If you can learn from the best, why settle for mediocrity? In this essay, we'll learn from the knowledge and experience of a well-known plastering expert. They provide priceless wisdom and actionable advice to help you conquer obstacles, stay out of trouble, and reach your full potential.

Without further ado, let's delve into the world of cement and gypsum plaster application and maintenance and learn the tricks of the trade for creating flawless, eye-catching finishes. Here are some tried-and-true methods for applying and maintaining plaster made from cement and gypsum:

Surface Preparation:

- Make sure there is no grease, dirt, or other debris in the area that will be plastered.

- Plaster should be applied after any cracks or uneven areas have been repaired.

- In warmer weather, especially, dampening the surface to slow down the plaster's evaporation rate is a good idea.

Mixing Plaster:

- Always use the recommended ratios and amounts of water specified by the manufacturer.

- Plaster and water should be combined slowly while stirring to prevent lumps.

- Wait a few minutes to use the slaked (rested) mixture.

Application Techniques:

- Start by applying a scratch coat, a rough layer of plaster that will aid in the adhesion of the subsequent coats.

- Spread the plaster around evenly with a trowel or a hawk and trowel.

- If necessary, apply additional coats and wait for each to dry before proceeding.

Finishing and Smoothing:

- If you want a smoother finish, use a steel trowel instead of a wooden float.

- If you don't want the trowel to get stuck in the plaster, wet it a little.

- To prevent trowel markings, move around in a circular motion.

Curing and Drying:

- Block out the sun and keep the breezes away from the freshly plastered surface.

- Make sure paint or other decorative finishes have enough time to cure before applying.

- For the plaster to cure properly, it should be kept damp by spraying it with water daily for a few days.

Maintenance:

- Check the plaster for deterioration and cracks regularly.

- Use the proper plaster restoration procedures to fix any cracks or chips quickly.

- If you want to keep the plaster from crumbling, keep it from getting too wet.

Cleaning:

- Dust and debris can be brushed off the plastered surface or use a vacuum cleaner.

- Cleaning tough stains requires only a mild detergent solution and a soft cloth.

- To protect the plaster, don't use anything abrasive or chemically aggressive.

- Always check the manufacturer's instructions for any plastering products you intend to use. If you have any questions about plastering or upkeep, it is best to ask a professional.

Conclusion

Sand, cement, and water combine to form cement plaster, which is both durable and long-lasting.

Gypsum plaster, made from gypsum powder, water, and additives, is durable and simple to apply. Cement plaster, manufactured by mixing cement and sand in a certain ratio, is placed to walls to serve as a protective layer and an aesthetic enhancement.

Cement plaster needs time to cure after application so it may harden and become more durable.

Walls and ceilings within buildings frequently feature gypsum plaster, a product of the mineral gypsum. It has excellent fire and soundproofing properties and is safe for the environment.

Water, sand, and Portland cement make up cement plaster, while gypsum powder is the main ingredient in gypsum plaster. Recommendation: Use gypsum plaster in moist places like bathrooms and kitchens.

Exterior and interior surfaces alike can benefit from the adaptability of cement plaster.

Because of its poor performance in wet conditions, gypsum plaster is only appropriate for use on interior walls and ceilings.

The two materials differ significantly in terms of setting time, thickness, non-toxic and anti-fungus properties, consumption, weight, acoustic qualities, the absence of shrinkage cracking, cost, and application time.

Gypsum plaster's setting periods are flexible, while cement plaster calls for at least a day's worth of drying time between coats.

While both cement plaster and gypsum plaster serve their respective purposes in the realm of plastering, the former is better suited to certain circumstances due to its superior raw materials, application area, setting time, thickness, properties, consumption, weight, acoustic attributes, and resistance to cracks.

To help you perfect your plastering skills, an expert offers advice on how to apply and maintain plaster.

The secret to a flawless, long-lasting plaster finish is in the surface preparation. Plastering should follow the restoration of any cracks or uneven spots. When combining plaster with water, do so carefully to avoid creating lumps. Scratch coating, steel trowel smoothing and finishing, curing and drying, maintenance, and cleaning are all necessary steps in the application process.

Regularly inspect the plaster for signs of damage and cracks, and apply the appropriate restoration techniques to repair any you find. Before using any plastering goods, make sure you read the manufacturer's directions and consult a professional if necessary.

Content Summary

- Comparing cement plaster and gypsum plaster to make an informed decision.

- Cement plaster made from sand, cement, and water is strong and long-lasting.

- Gypsum plaster is created from gypsum powder, water, and additives and has a smooth finish.

- Cement plaster protects against moisture, improves fireproofing, and enhances the appearance of walls.

- Gypsum plaster provides fire protection and acts as a sound barrier.

- Gypsum plaster is eco-friendly and regulates moisture levels.

- Cement plaster is versatile and can be used for both interior and exterior surfaces.

- Gypsum plaster is suitable for interior walls and ceilings but not damp environments.

- Cement plaster requires a minimum drying time of one day between layers.

- Gypsum plaster has adjustable setting times for swift application of subsequent coats.

- Cement plaster has a minimum thickness of 10 mm, while gypsum plaster requires different thicknesses for walls and ceilings.

- Cement plaster is susceptible to mold and mildew growth, while gypsum plaster discourages it.

- Cement plaster covers approximately 16-18 square feet per 40kg bag, while gypsum plaster covers 18-21 square feet per 25kg bag.

- Cement plaster is denser and heavier than gypsum plaster.

- Both cement plaster and gypsum plaster offer comparable acoustic qualities.

- Cement plaster is prone to shrinkage cracks, while gypsum plaster mitigates cracking.

- Cement plaster is costlier due to longer application time, while gypsum plaster reduces labor expenses.

- Professional tips for plaster application and maintenance.

- Surface preparation is crucial before applying plaster.

- Proper mixing techniques and water ratios are essential.

- Scratch coat aids in subsequent coat adhesion.

- Steel trowel provides a smoother finish.

- Curing and drying processes are important for proper plaster hardening.

- Regular checks for cracks and deterioration in plaster.

- Use appropriate restoration procedures for fixing cracks or chips.

- Proper cleaning techniques to remove dust and debris from plastered surfaces.

- Mild detergent and soft cloth for cleaning tough stains on plaster.

- Avoid abrasive or chemically aggressive cleaners to protect the plaster.

- Always refer to manufacturer's instructions for plastering products.

- Consult a professional for any questions regarding plastering or upkeep.

FAQS About Plaster

Yes, cement plaster can be used for interior walls. It provides a strong and durable finish, making it suitable for areas where strength and resistance to wear are important. Cement plaster is commonly used in basements, foundations, and other interior surfaces that require a robust wall finish.

However, it's worth considering that cement plaster may not provide the same level of smoothness as gypsum plaster. If you desire a perfectly smooth and leveled surface for your interior walls, gypsum plaster might be a better option. Gypsum plaster is known for its ability to create a seamless and flawless finish, which is often desired in interior spaces.

Gypsum plaster is generally not recommended for exterior applications due to its lower resistance to moisture and limited durability compared to cement plaster. Exterior surfaces are exposed to harsh weather conditions, and cement plaster provides better protection against moisture infiltration and damage.

Cement plaster is the preferred choice for exterior applications as it offers superior strength, durability, and resistance to the elements. It can withstand temperature changes, moisture, and other external factors, making it suitable for long-lasting finishes on exterior walls.

Gypsum plaster is not recommended for areas with high humidity levels, such as bathrooms, kitchens, or areas prone to water splashes. Although gypsum plaster has some moisture-resistant properties, it is not as suitable as cement plaster for areas with excessive moisture.

High humidity can cause gypsum plaster to deteriorate over time, leading to potential mold growth or other moisture-related issues. In such areas, it is advisable to use cement plaster or consider alternative moisture-resistant materials specifically designed for humid environments.

Yes, there are a few essential preparations to consider before applying gypsum plaster:

- Surface cleaning: Ensure that the surface is clean, free from dust, grease, and loose particles. Cleaning the surface thoroughly helps in achieving better adhesion and a smooth finish.

- Priming: It is recommended to apply a primer or a coat of diluted gypsum plaster on the surface before the actual application. Priming helps in improving the bond between the surface and the plaster, enhancing the overall finish.

- Mixing consistency: Follow the manufacturer's instructions for mixing gypsum plaster with water to achieve the right consistency. Proper consistency ensures easier application and a uniform finish.

- Application technique: Gypsum plaster is typically applied in multiple thin layers. Each layer should be allowed to dry partially before applying the next layer. This helps in preventing cracks and achieving a smooth and even finish.

Yes, gypsum plaster is inherently fire-resistant. Gypsum, the main component of gypsum plaster, contains water molecules within its crystalline structure. When exposed to fire, the water molecules are released as steam, acting as a barrier to slow down the spread of flames.

Due to its fire-resistant properties, gypsum plaster is commonly used in fire-rated assemblies and structures. It helps to improve the fire safety of buildings by providing additional time for occupants to evacuate and reducing the spread of fire within a space.

However, it's important to note that gypsum plaster is not completely fireproof. In the event of a severe fire, prolonged exposure to high temperatures can eventually cause the plaster to degrade. Therefore, it is crucial to adhere to building codes, regulations, and fire safety measures when incorporating gypsum plaster into a construction project.